How Phase Change Materials (PCMs) stabilize temperature-sensitive shipments

Temperature control without concessions

In the logistics of temperature-sensitive products, one factor is critical: stability. Just a few degrees of deviation – or just a few minutes out of specification – can lead to loss of product quality, rejection or legal liability. Think of refrigerated medicines, laboratory samples or perishable food: if the temperature is off, the whole process is for naught.

Phase Change Materials (PCMs) are designed to eliminate that risk. Unlike standard water packs or gel packs, which heat up gradually, a PCM maintains an exact melting point – for example, 2 °C, 5 °C or -21 °C – for an extended period of time. This creates a controlled temperature zone in which products can be safely transported, even under varying external conditions.

Every day Coolpack advises companies that demand reliability and accuracy in their cold chain. In this article, we explain how PCMs work, what differentiates them from other refrigerants and when they are the only wise choice.

Customization for your unique challenge

Choose solutions that fully meet your needs. At Coolpack, we’re ready with innovative and reliable products for conditioned transport. Together we will be happy to discuss what works for you. Discover what’s possible. Click below for more information.

Specialist in the market

For conditioned transport

Always a solution

Perfectly tailored to your situation

Fast delivery

Your products safe and fresh

Trusted quality

Known to perform time and again

What makes PCMs unique?

Phase transition as a thermal buffer

Phase Change Materials are materials that change phase at a fixed melting point – usually from solid to liquid. During this transition, they take latent heat up (or release it) without the temperature rising or falling. This allows them to maintain a constant temperature over long periods of time, regardless of external influences.

For example, a PCM with a melting point of 5 °C will hold exactly that temperature during transport as long as the melting process continues – ideal for products that need to stay within 2-8 °C.

PCMs are available in various temperature ranges, such as:

- -21 °C (alternative to dry ice)

- 2-8 °C (refrigerated pharma or food products)

- 15-25 °C (room temperature stable medical goods)

This is how PCMs function in packaging

Precision by design

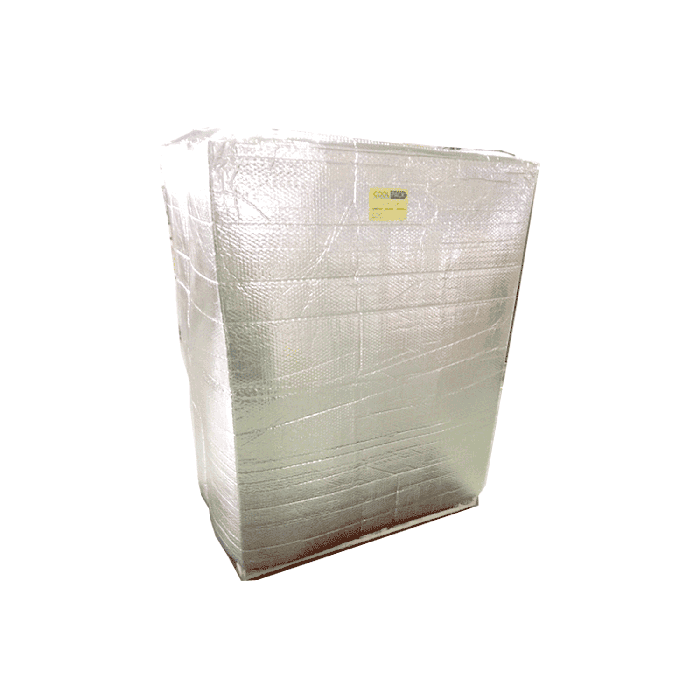

PCMs are applied in the form of cooling elements or cassettes, placed around the product in insulated packaging. Once the product is packed, the PCM begins to work: as the temperature changes, it slowly melts, absorbing heat and keeping the interior space exactly within specification.

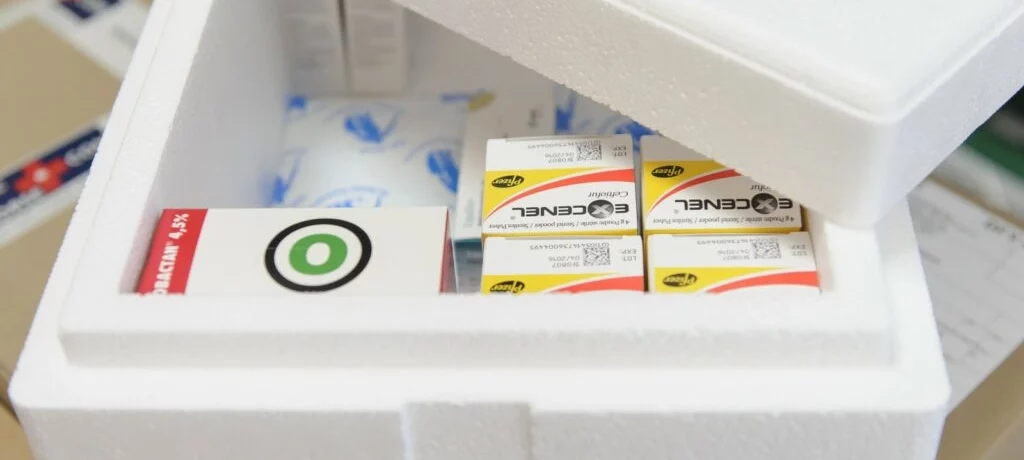

Case example

A pharmaceutical company ships a biological drug that must remain between 2 °C and 8 °C. Instead of water packs, it uses PCM cartridges with a melting point of 5 °C. As a result, the temperature inside the box remains exactly 5 °C for 48 hours, even in outdoor temperatures of up to 25 °C. Thanks to this stability, the shipment meets all GDP requirements – without active cooling.

Reusability and lifecycle

PCMs are robust and reusable, if properly conditioned:

- They require precise pre-conditioning (freezing temperature should match melting point);

- The number of reuse cycles varies by composition (organic, inorganic or eutectic);

- Coolpack provides packaging in which PCMs continue to perform safely, leak-free and consistently.

Why choose PCM instead of water packs?

1. Accuracy under pressure

Waterpacks extract heat over a wider range (0-15 °C) when melting. PCMs do so at a single sharp point – resulting in: temperature stability without fluctuations.

2. Validation and compliance.

Companies operating under GDP, HACCP or ISO 13485 benefit from reproducible performance. PCMs are predictable and reliable, ideal for validation and audit processes.

3. Longer duration of action

With proper insulation, PCMs can take shipments 48 to 72 hours within the proper range. This makes them suitable for intercontinental transport or multi-day distribution without active refrigeration.

4. Less risk of damage

Water packs lying directly against the product can cause freezing damage. PCMs are safe on contact and maintain exactly the desired temperature.

When is a PCM the best choice?

Pharmaceutical and medical applications

PCMs are indispensable for:

- Vaccines and injectables with narrow temperature range;

- Clinical trials in which all shipments must perform equally;

- Samples with provable cold chain compliance.

Food logistics with high demands

When exporting delicacies such as cheese, fish or meat – or in premium meal boxes – PCMs are the guarantee of quality on longer routes or warmer climates.

Biotech, laboratories and diagnostics

Reagents, cell cultures, DNA and RNA samples: in these shipments, one degree of deviation is already fatal. PCMs provide the control needed in sensitive chains.

Conclusion and advice

Phase Change Materials (PCMs). combine precision, predictability and thermal intelligence in one cooling solution. They are designed for situations where temperature control is not an option, but a requirement. From validation required pharmaceutical chains to high-value box exports, PCMs provide stable conditions where traditional refrigerants fall short.

Coolpack supports companies in the selection and application of the right PCM system, tailored to route, duration, temperature range and regulations. We deliver packaging that performs under pressure – and where every degree counts.

For those seeking certainty rather than estimates, a PCM is not a luxury, but a basic requirement.

Sustainability Coolpack and CSR

At Coolpack, we are aware of our responsibility to contribute to society. Both in terms of sustainability and society as a social body.

We weigh the interests of the customer, the environment and society, as well as ourselves as an organization, in all business decisions. In this way, we achieve balanced business operations and together ensure an ever better world.

Product groups

Customer Cases

Contact

- +31 (0)33 457 19 82

- info@coolpack.nl

-

Industrieweg 11b

1566 JN Assendelft

Related blogs

Growing popularity of frozen foods in Europe: driving innovation in temperature-controlled shipments

The European temperature-controlled shipping market is experiencing significant growth, mainly due to the growing popularity of frozen foods. According to […]