The benefits of Phase Change Materials (PCMs) in cold chain logistics

In the ever-changing landscape of cold chain logistics, maintaining accurate temperature control is crucial. This can be achieved with Phase Change Materials (PCMs) – a revolutionary solution that offers many benefits for companies looking to optimize their cold chain operations. In this article, we discuss six compelling reasons why PCMs should be your first choice.

High precision temperature control

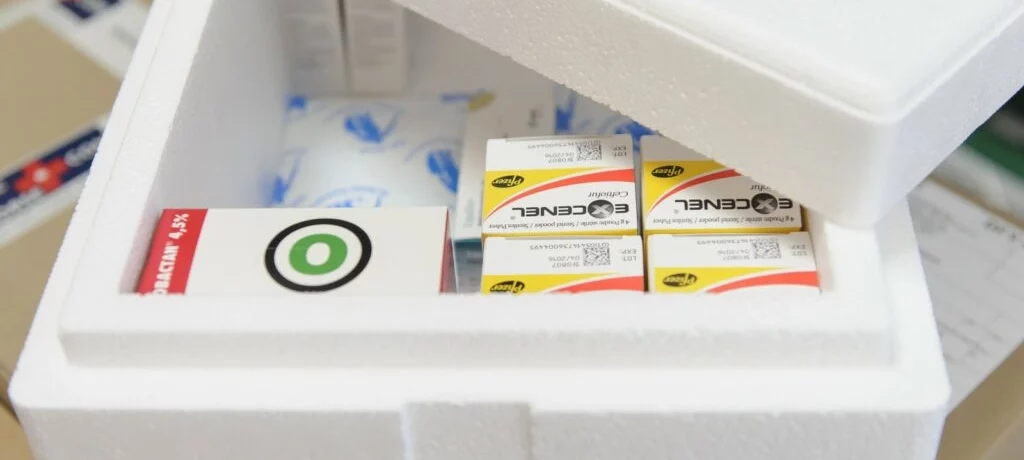

One of the key advantages of PCMs is their ability to store and release thermal energy, effectively counteracting temperature fluctuations. This unique property enables PCMs to maintain strict temperature limits and ensure the quality and integrity of your temperature-sensitive products. By including PCMs in your cold chain packaging, you can ensure that your goods remain within the desired temperature range, minimizing the risk of spoilage or degradation.

Comprehensive temperature control

Another benefit of PCMs is their comprehensive temperature control for your cold-chain packaging. By strategically placing PCMs in your shipping containers, you can take advantage of their reloading capabilities during cold storage. So even if your shipment experiences unexpected delays or transit times are longer than expected, PCMs will keep temperatures stable, significantly reducing the risk of spoilage. PCMs give you peace of mind knowing your products will be protected for longer periods of time.

Customization for your unique challenge

Choose solutions that fully meet your needs. At Coolpack, we’re ready with innovative and reliable products for conditioned transport. Together we will be happy to discuss what works for you. Discover what’s possible. Click below for more information.

Specialist in the market

For conditioned transport

Always a solution

Perfectly tailored to your situation

Fast delivery

Your products safe and fresh

Trusted quality

Known to perform time and again

Elimination of dry ice

Traditionally, many cold chain logistics relied on dry ice to maintain low temperatures. However, dry ice brings its own challenges, including strict regulations, safety concerns and the need for continuous monitoring. PCMs offer a superior alternative and completely eliminate the need for dry ice. By using PCMs, you can streamline your cold chain operations, avoid the hassle of complying with dry ice regulations and improve the safety of your logistics personnel.

Embracing the green choice

In today’s environmentally conscious world, sustainability is a top priority for companies in all industries. PCM-based reusable shippers offer a green solution to your cold chain needs. By choosing reusable packaging materials with PCMs, you can significantly reduce your packaging waste and minimize your carbon footprint. This not only contributes to a greener supply chain, but also demonstrates your commitment to sustainability. This will improve your brand’s reputation among environmentally conscious consumers.

Preventing cold shocks

Rapid drops in temperature, also known as cold shock, can pose significant risks to certain temperature-sensitive products. By combining frozen cold packs with PCMs, you can effectively counteract and prevent cold shock. The PCMs act as a buffer by gradually absorbing and slowly releasing the cold energy from the frozen packs for a more controlled and stable temperature transition.

Versatility in all seasons

Versatility is key in cold-chain logistics, and PCM-based thermal packaging offers just that. PCMs allow you to adapt your packaging solutions to different shipping scenarios and seasonal variations. Whether you are shipping products during the scorching heat of summer or icy winter temperatures, PCMs can be customized for optimal temperature control. Investing in PCM-based packaging gives you a universal solution that adapts to your specific needs. This simplifies your logistics processes and ensures year-round product protection.

PCMs as the way forward

Durable Phase Change Materials offer numerous benefits to companies looking to improve their cold chain logistics, including high precision and comprehensive temperature control and eliminating the need for dry ice. PCMs have proven to be a versatile and reliable solution. By embracing PCM-based thermal packaging, you can streamline your operations, protect your products and deliver unmatched quality to your customers – in any season!

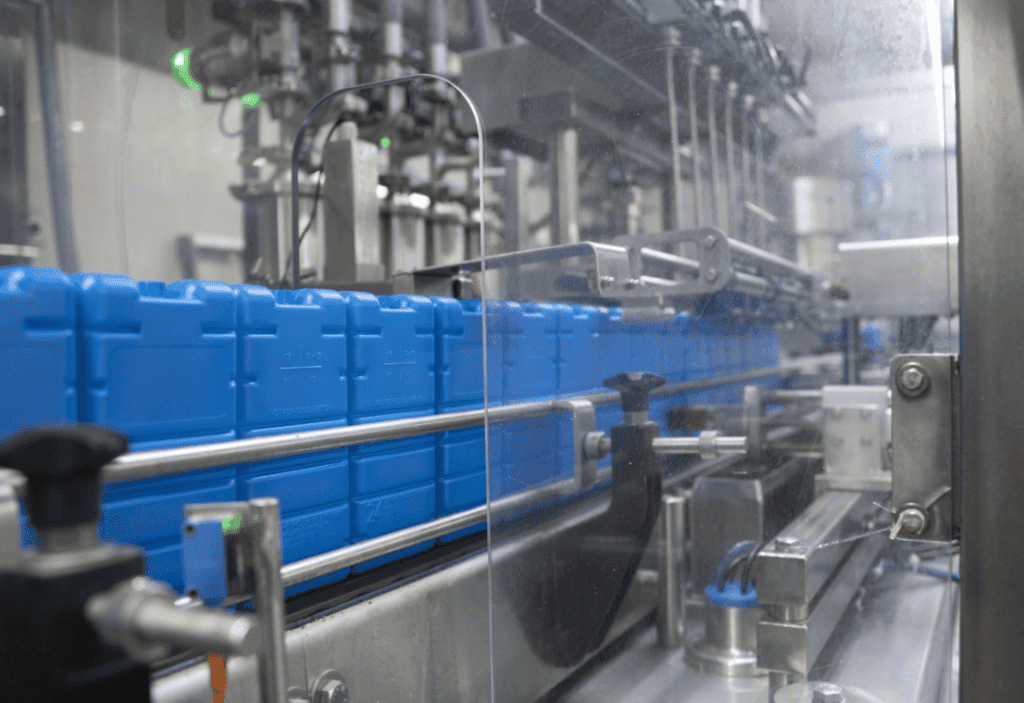

PCM technology in Coolpack’s solutions

As a pioneer in sustainable cold chain solutions, Coolpack has integrated PCM technology into its refrigeration solutions and set new standards in the industry. By leveraging Coolpack’s expertise, companies can achieve superior temperature control and sustainability to ensure the integrity and quality of their products – from origin to destination. Contact Coolpack’s product specialists today to learn how our advanced PCM solutions can revolutionize your cold chain logistics.

Sustainability Coolpack and CSR

At Coolpack, we are aware of our responsibility to contribute to society. Both in terms of sustainability and society as a social body.

We weigh the interests of the customer, the environment and society, as well as ourselves as an organization, in all business decisions. In this way, we achieve balanced business operations and together ensure an ever better world.

Product groups

Customer Cases

Contact

- +31 (0)33 457 19 82

- info@coolpack.nl

-

Industrieweg 11b

1566 JN Assendelft