Do frozen foods really retain their nutrients?

Freezing food is an essential part of the modern food chain. Lowering temperatures below freezing virtually halts microbial growth, keeping products safe for months. Yet there is debate about the extent to which nutritional value is retained after freezing, transportation and storage. At a time when food is being moved around the world and the demand for convenience and shelf life is growing, it is important to understand what freezing does to vitamins, minerals and bioactive compounds. For professionals in food processing and temperature-controlled logistics, understanding these processes is crucial to ensuring product quality. Nutrient retention depends not only on the freezing method, but also on packaging, transport temperature and stability throughout the chain.

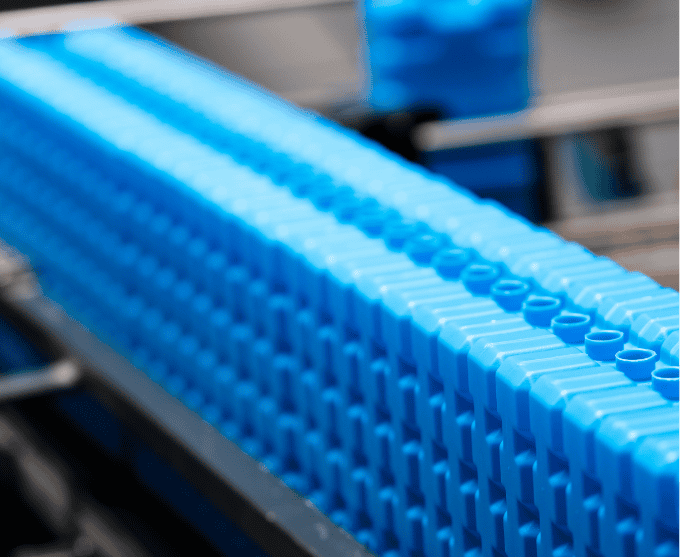

Customization for your unique challenge

Choose solutions that fully meet your needs. At Coolpack, we’re ready with innovative and reliable products for conditioned transport. Together we will be happy to discuss what works for you. Discover what’s possible. Click below for more information.

Specialist in the market

For conditioned transport

Always a solution

Perfectly tailored to your situation

Fast delivery

Your products safe and fresh

Trusted quality

Known to perform time and again

Freezing as a preservation technique

Freezing is a physical process in which water in food changes from liquid to solid phase. This lowers microbial activity and inhibits enzymatic activities that cause spoilage. At sufficiently low temperatures (-18 °C or below), the kinetics of oxidation and hydrolysis are greatly slowed. The goal is not only to extend shelf life, but also to preserve as much nutritional value as possible. Under controlled conditions, vitamins, minerals, and antioxidants remain largely intact. In contrast, poorly controlled freezing or thawing processes can lead to loss of nutrients, especially the water-soluble ones.

Physical and chemical influences on nutrients

Freezing creates ice crystals in the cells of the product. The size and distribution of these crystals determine the degree of cell damage. Large crystals, typical in slow freezing, tear cell membranes and cause “drip loss” upon thawing, resulting in loss of water-soluble components such as vitamin C and folic acid.

Quick freezing, such as Individual Quick Freezing (IQF), minimizes this damage by keeping the crystals smaller. As a result, structure, moisture balance and micronutrients are better preserved.

In addition, oxygen exposure is a chemical risk factor. During storage or transportation, oxidative reactions can break down fatty acids and vitamin E. Therefore, airtight, vapor and oxygen barrier films are important for quality maintenance.

Pretreatment and process control

Blanching is a standard step in vegetables before they are frozen. Brief heating deactivates enzymes that would otherwise cause browning and vitamin breakdown. However, the duration and temperature must be precisely matched: too short leads to enzyme activity, too long causes unnecessary vitamin loss. For optimal retention of vitamin C, for example, 1-3 minutes at 85-95 °C is effective, depending on product thickness.

Time between harvest and freezing is a second critical factor. Studies show that in spinach or broccoli frozen immediately after harvest, vitamin content often remains higher than the same vegetable that spends three days “fresh” in the chain. Rapid cooling after harvest and cold intermediate storage before freezing are thus essential for maintaining nutritional quality.

Storage and transportation conditions

The storage stage determines how well the initial quality is maintained. Guideline values from the Codex Alimentarius and EU regulations recommend -18 °C as the standard temperature for frozen foods. Every 5 °C increase approximately halves shelf life and accelerates nutrient degradation. Temperature fluctuations also lead to re-freezing, which causes ice crystal growth and texture deterioration.

For logistics professionals, this means that temperature-controlled logistics with stable set points, calibration of sensors and well-insulated packaging is essential.

Data logging according to EN 12830 is increasingly used to record temperature variations. Such data can be used to substantiate the relationship between transport conditions and product quality, a requirement in certification systems such as ISO 22000 and GDP.

Defrosting and preparation

During thawing, water-soluble vitamins can be lost through the released moisture. Thawing at 0-4°C and preparation while retaining moisture (e.g., steaming or stir-frying) can reduce that loss.

In addition, the duration between thawing and consumption affects retention. Once products are thawed, enzyme activity increases again, which especially increases susceptibility to vitamin C degradation.

Packaging and thermal efficiency

Packaging plays a key role in maintaining temperature and oxygen protection. In the cold chain, insulating packaging and phase-change materials (PCMs) are used to dampen temperature fluctuations.

The thermal efficiency of a package is determined by insulation value, PCM capacity, and sealing. When transported or stored with irregular temperatures, PCM elements can help keep within the desired temperature range.

For nutritional value, this means fewer temperature excursions and less chance of oxidative degradation of micronutrients.

In addition, the use of monomaterial packaging is gaining ground to improve recycling. Here, it is crucial that barrier properties do not come at the expense of thermal performance. Properly balanced packaging thus combines food safety, nutrient preservation and environmental efficiency.

Summary practice guidelines

- Minimize time between harvesting and freezing.

- Use quick-freeze techniques to limit ice crystal growth.

- Keep storage temperature stable below -18 °C with validated measuring equipment.

- Defrost controlled at low temperature, and process product while retaining moisture.

- Choose packaging with high thermal efficiency and sufficient barrier properties.

- Implement continuous data logging for temperature monitoring throughout the chain.

Under these conditions, frozen foods typically retain 80-95% of their original nutritional value, depending on product type and process stability.

How Coolpack contributes to maintaining quality in frozen food logistics

The preservation of nutrients in frozen foods depends not only on the production process, but also on stable temperature control during transport and storage. Coolpack supports this step in the chain with validated cooling and freezing solutions designed for long-term thermal stability. Our Phase Change Materials (PCMs) and cooling elements offer precise temperature ranges, such as -16 °C and -21 °C, which allow frozen products to retain their quality during distribution and storage.

Combined with insulation packaging such as EPS, EPP and cardboard solutions, this ensures controlled heat transfer and minimal temperature fluctuations. Thanks to ISO 9001 and ISO 14001 certified production processes, Coolpack ensures constant quality and environmental responsibility in the cold chain.

Sustainability Coolpack and CSR

At Coolpack, we are aware of our responsibility to contribute to society. Both in terms of sustainability and society as a social body.

We weigh the interests of the customer, the environment and society, as well as ourselves as an organization, in all business decisions. In this way, we achieve balanced business operations and together ensure an ever better world.

Product groups

Customer Cases

Contact

- +31 (0)33 457 19 82

- info@coolpack.nl

-

Industrieweg 11b

1566 JN Assendelft

Related blogs

Global cold chains are the backbone of food and medicine logistics. Yet this network is under pressure. Extreme weather, stricter […]

Food waste is a structural problem worldwide within both the food chain and the broader sustainability agenda. According to recent […]

Amid escalating global concerns about environmental pollution, sustainability has emerged as an important trend in the European market for temperature-controlled […]